These days, it’s all about the steps – about counting how many one has taken in any given day, via one device or another. Have I reached the exalted threshold of 10,000? Or must I get myself off the couch and trudge around the block? More to the point, have I gone far enough to justify seconds on dessert?

All pertinent questions, and all questions many of us are asking ourselves, now that the wearables have become all the rage. Whether it’s a FitBit or smart watch or some other gadget, some 57 million Americans have taken to wearing devices that track not only their exercise rate but also their vital signs, sleep patterns or caloric intake. It is estimated that the wearable market is currently an industry worth between $25 billion and $33 billion annually, and one that will soar past $63 billion by 2027.

Such is Americans’ obsession with wearables, in fact, that some experts worry that it could lead to mental-health issues – that folks will equate their step count to their self-worth. But in a society that has grown too sedentary, too obese and too prone to chronic conditions like heart disease, cancer and diabetes, every step (whether literal or figurative) would appear to be a positive one.

As Johns Hopkins Medicine cardiologist Seth Martin said on that organization’s website:

“Fitness trackers are a great tool for heart health. Being more active and changing your habits is important, but it can be difficult. Tracking likely helps a lot of people when combined with a clear goal to shoot for.”

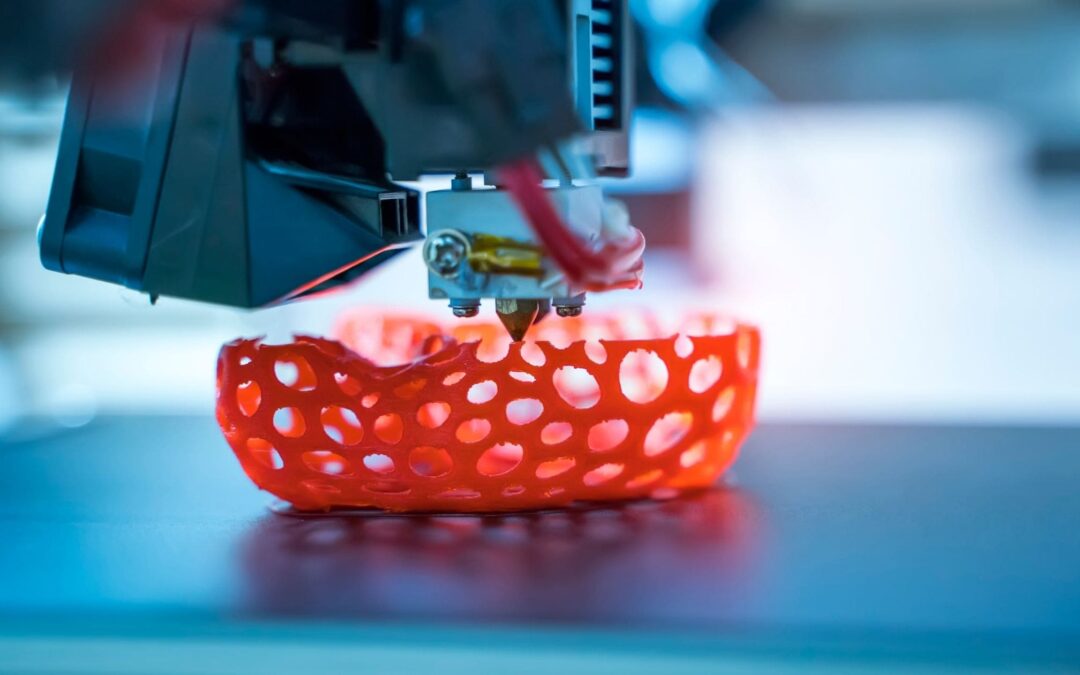

Given the popularity of such gadgetry, it should come as no surprise that innovation in the field is ongoing; everybody, it seems, wants to be on the cutting edge. Nor should it be a surprise that 3D printing is playing an increased role in this sector.

Consider the development in 2011 by a team from the University of Arizona’s School of Engineering of a health monitor that never needs to be recharged. This device, labeled “a completely new concept” by Arizona professor Philipp Gutruf, features 3D-printed mesh that can be fitted to different body parts, and which requires no adhesives. Moreover, it is embedded with miniature sensors that enable it to track different biometrics, and draws its power from radio signals – known as “far-field” energy harnessing, according to a UA news release.

Also notable were the developments at two Korean universities of biosensors that use 3D-printed frameworks – one made of a polyvinylidene fluoride (PVDF)/barium titanate (BTO) composite, the other of a sugar scaffold (eventually dissolved) which was injected with a silicone elastomer filler. The first of these sensors was piezoelectric, meaning that it draws its energy from applied stress. One example was when it was fitted into a taekwondo belt, which is constantly subjected to the blows of the competitors in that martial art.

Certainly 3D printers come into play in other aspects of sports, as when it is used to customize equipment that protects athletes from injury and leads to improved performance. Moreover, it has been found that such items reduce the industry’s carbon footprint and enable increased participation by disabled competitors.

But the greatest impact of all is in the day-to-day use of fitness trackers. Everyone seems to have one, and everyone stands to benefit. And those produced by 3D printers seem to have as much promise as any given their durability, flexibility and user friendliness.